- Descriere

- Review-uri (0)

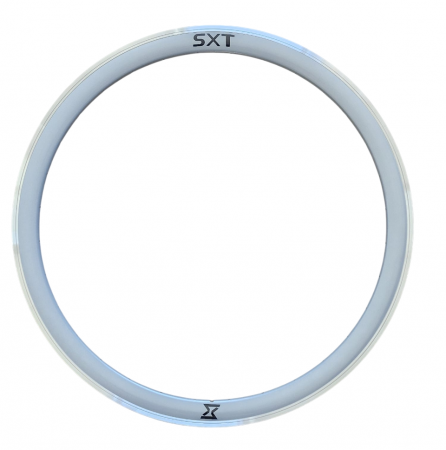

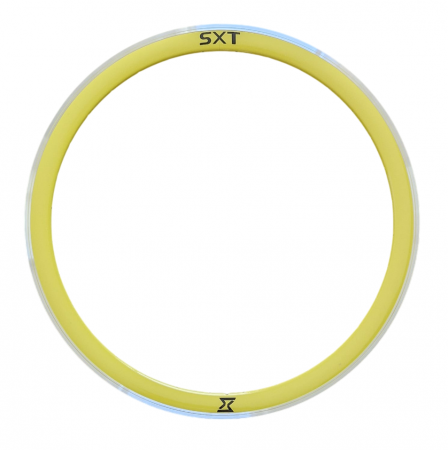

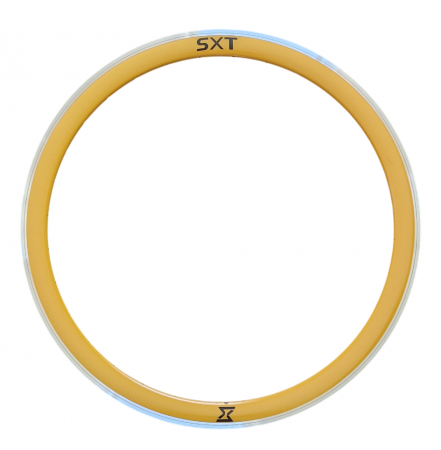

TR30 MTB rim, AL6061, advanced 4D smart multi-angle drilling,super strength sleeved, tubeless ready

Net weight:575g/pc(26")/595g/pc(27.5")/630g/pc(29")

Finish:Pre-anodizing

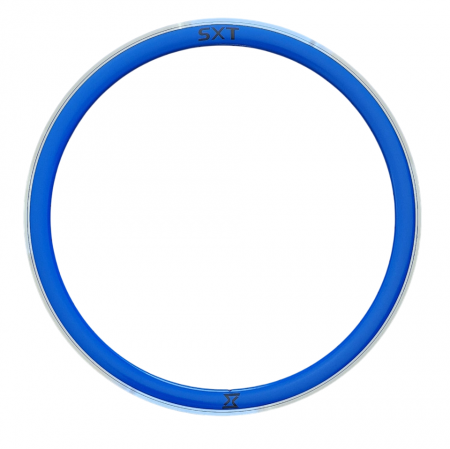

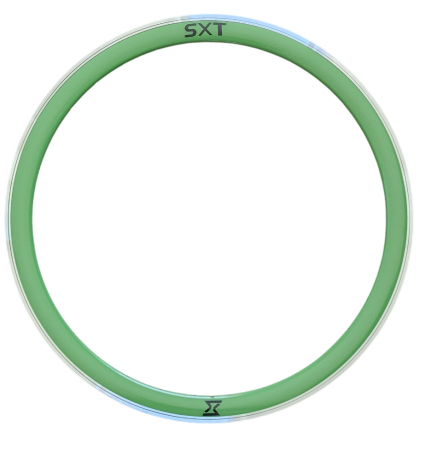

Colour: Black with logo white

Field of application:free ride/down hill

Recommended SYS weight max.:140kg

Material:aluminum alloy6061

Joint:sleeved

Rim type:tube/ tubeless ready

Brake interface:disc

Diameter:559x30(26 inches)/584x30(27.5 inches)/622x30(29 inches)

ERD:526mm(26 inches)/551mm(27.5 inches)/589mm(29 inches)

Inner width:30mm

Outer width:35mm

Rim height:24mm

Recommended tire:26~29"x2.5~3.2"

Spoke holes:Non eyelet,4D smart angle-WHAT IS THE DIFFERENCE BETWEENGENERAL DRILLING AND 4D SMART ANGLE DRILLING The qeneral driling holes are vertical angle holes, the assemblyholes and spokes holes are completely perpendicular to the rimcenter point. this processing is more convenient for machining andproofreading, with high production efficiency. There is a drawbackthat when assembly the wheel group since the lange hole and spokeshole allways have about 6 deqrees angles in both lonqitudinal andradial directions, so the connection between spoke and nipples willalways have a bend and can never be a straight line. lf the tension onthe spokes is a little hiqher, it would prone to breakage while ridingthe 4D smart angle drilling technology made the driling angle isslightly inclined. according to the pulling angle of each spoke, it is inthe lonqitudinal and radial direction, each offset is about 6 deqreesso that it is in line with the angle of flange to ensure the nipple andspokes to form a straight line as much as possible, Thus fundamen-tally solve the long-term problem of spokes pulling angles.

Holes count:32

Valve:FV/presta(Φ6.5mm)

![Janta SXT TR30 29 (622-30C)- 32H Negru [1] Janta SXT TR30 29 (622-30C)- 32H Negru [1]](https://gomagcdn.ro/domains2/bikestylish.ro/files/product/large/janta-sxt-tr30-29-622-30c-32h-negru-488676.jpg)

![Janta SXT TR30 29 (622-30C)- 32H Negru [2] Janta SXT TR30 29 (622-30C)- 32H Negru [2]](https://gomagcdn.ro/domains2/bikestylish.ro/files/product/large/janta-sxt-tr30-29-622-30c-32h-negru-000250.jpg)

![Janta SXT TR30 29 (622-30C)- 32H Negru [3] Janta SXT TR30 29 (622-30C)- 32H Negru [3]](https://gomagcdn.ro/domains2/bikestylish.ro/files/product/large/janta-sxt-tr30-29-622-30c-32h-negru-946312.jpg)

![Janta SXT TR30 29 (622-30C)- 32H Negru [4] Janta SXT TR30 29 (622-30C)- 32H Negru [4]](https://gomagcdn.ro/domains2/bikestylish.ro/files/product/large/janta-sxt-tr30-29-622-30c-32h-negru-005543.jpg)

![Janta SXT TR30 29 (622-30C)- 32H Negru [5] Janta SXT TR30 29 (622-30C)- 32H Negru [5]](https://gomagcdn.ro/domains2/bikestylish.ro/files/product/large/janta-sxt-tr30-29-622-30c-32h-negru-271341.jpg)